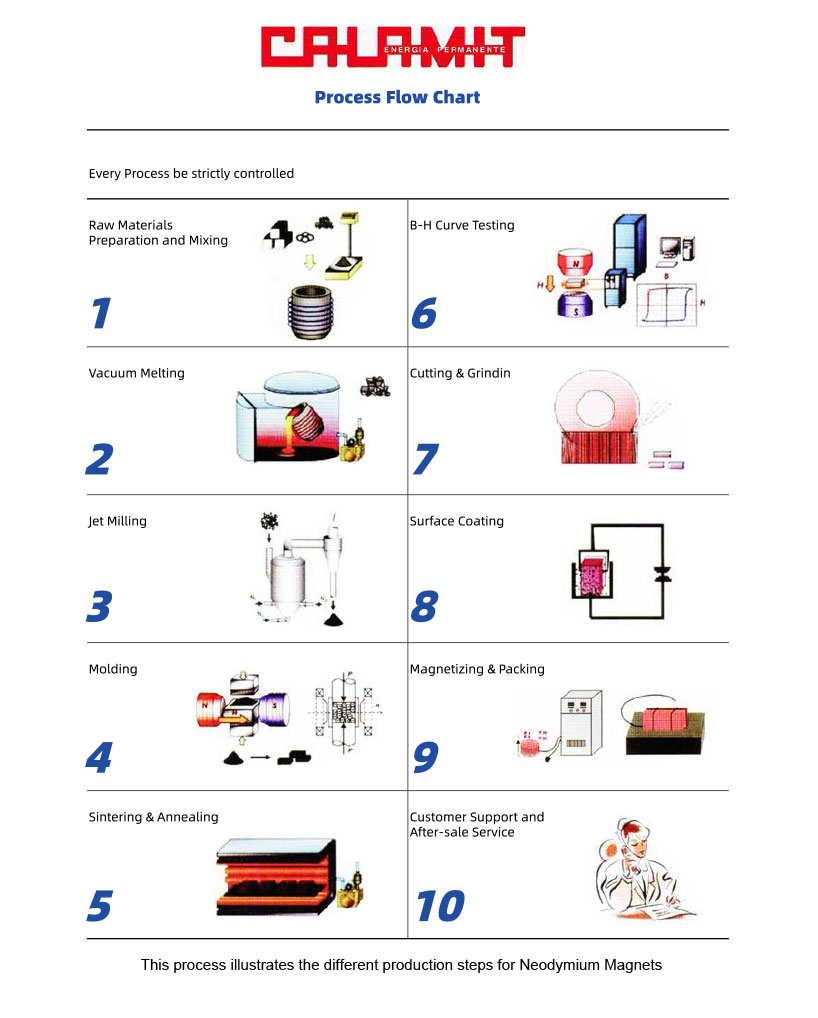

The rare earth magnets (Neodymium-Iron-Boron) are the most technologically advanced products in the market.

They are produced via sintering in a vacuum. The Neodymium-Iron-Boron is radically changing modern technology. There is no field of application which has been exclused by the use of these new super magnets.

Hard disks and computers operate 10 times faster than before, when simple Alnico Magnets were used.

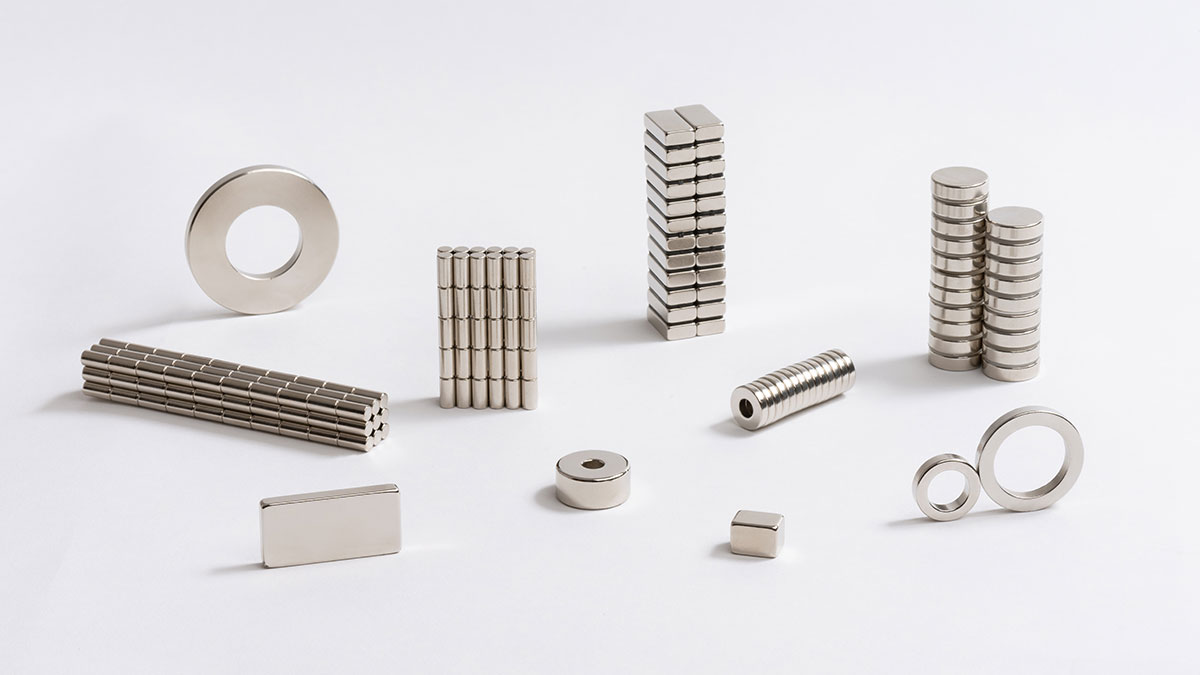

Neodymium Magnets drastically increased the performance of all electric motors, speakers have been miniaturized and also have become more powerful, proximity switches work at triple distances, and we could go on for hours listing all the sectors that have undergone extreme benefits thanks to the advent of this new magnetic composition.

First synthesized by mistake by an engineer from Fujitsu, Neodymium right away became a fundamental material for the production of high technology equipment. Initially (around 1990), the first formulas were capable of reaching a power of 35 MGOE (or 7 times more than traditional material available).

Today Neodymium grades that arrive up until 52 MGOE are commonly available and physicists assert that in the future we will be able to reach 80 MGOE with further unthinkable results in final performance. Neodymium Iron Boron is parts of the Rare Earth family.

The Rare Earths, despite their name, are not as rare as one might think. The main problem is finding rich and pure deposits that can justify long term production. Once the sites have been found, however, the second big problem is that of the separation of various metals from each other, and this technique is very expensive and polluting.

China, which has around 40% of the Rare Earths, is lucky enough to have two big sites, one close to Batou, bordering Mongolia, and one in the South, and both are very pure and very rich in material. Thanks to these two Neodymium deposits and a pricing policy stuck in time, China (which currently produces around 97% of world demand) convinced the rest of the world that there was no need for alternative producers and, at the moment in which the few competitors stopped producing (USA, CANADA, GERMANY, AUSTRALIA, etc.), the Chinese found themselves with a worldwide monopoly on the product. At that point the prices literally went crazy.

Between July 2010 and September 2011, Neodymium and praseodymium, Terium and Dysprosium prices (used in Neodymium magnets to increase resistance to temperature) increased up to 800%!!!! Luckily, since September 2001 the prices of all Rare Earths have decreased, but they are still high compared to the past, and price volatility is a constant.

Japan, the main user of Neodymium and Rare Earths in general, was literally blocked by Chinese politics and had no alternative.

In order to understand the strategic importance of this product, it is enough to see that the Japanese considered the possibility of starting an extraction in the Sea of Japan at 3000 meters in depth, with enormous costs, but that would allow autonomy from China. Currently the opening of various Rare Earth mines are being studied around the world, but even in the best of cases no production can be predicted for another 5 years, provided that the right site is even located.

Moreover, we should consider that other Rare Earths are strategic for high end technology (the production of light bulbs, computer screens, batteries for electric cars, cellular phones, fluorescent light bulbs, etc.) and that we therefore cannot do without them.

Initially, Neodymium could resist up to 120°C, after which the material tended to demagnetize. This greatly reduced the application fields, but today new technology has raised this limit to 230°C. The issue of corrosion has also been solved, thanks to innovative coating techniques that allow for a time guaranteed protection.

Usually Neodymium magnets are protected with special zinc or nickel baths, but sometimes also with copper or other special materials.

.jpg)

.jpg)