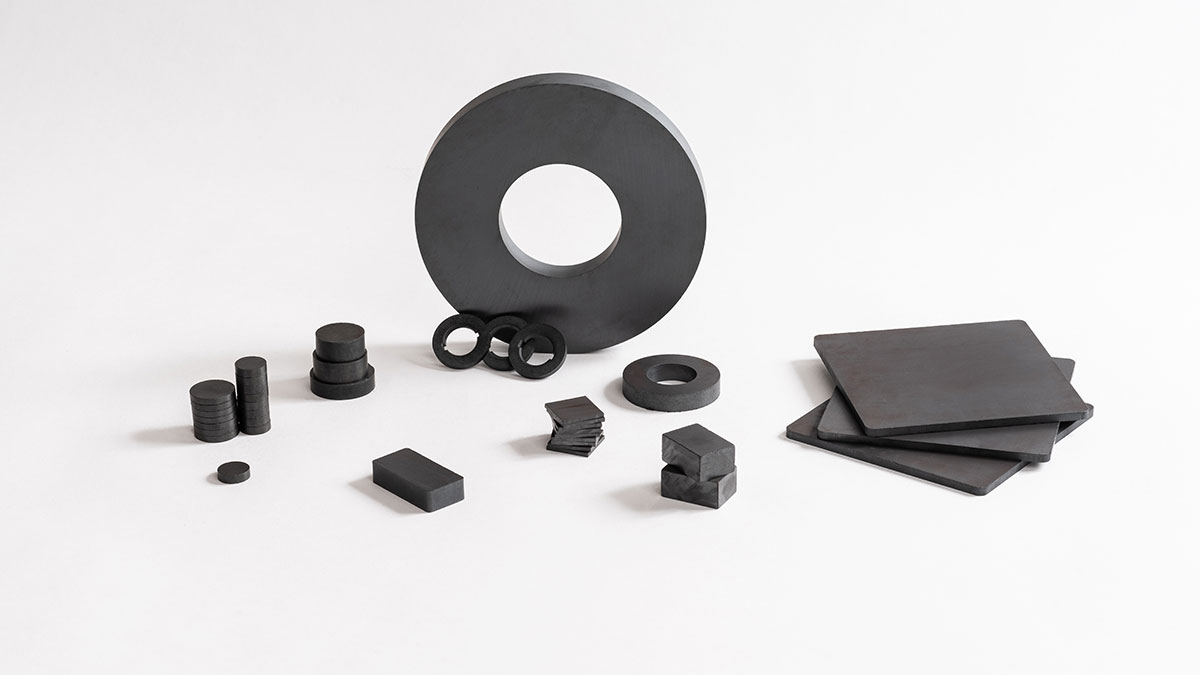

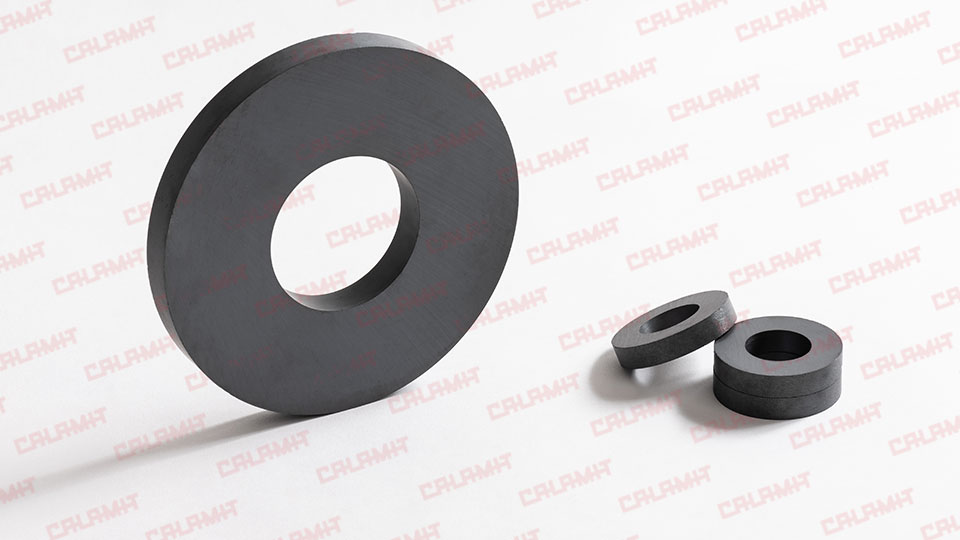

Patented in 1952 for its excellent price/quality ratio, it is by far the most common magnetic material. Composed of a mixture of iron oxide and barium carbonate (or strontium), ferrite is obtained thanks to a sintering process, either dry or wet.

For practical reasons the tables show only some standard measures. We therefore recommend you to ask for the measurements most suitable to your final use.

It is very likely that there are similar or adaptable measures.

Standard tolerances:

±2% on length and width.

±0,1 mm on thickness.

Ferrite Magnetic Circuit

The tractive force for of a permanent magnet depends on three fundamental factors: the volume, the type of magnetic material and the magnetic direction. In addition to these three points, there is the possibility of circuiting the magnet in question through simple soft iron.

In the diagrams you can see that a permanent magnet, which is axially magnetized through its thickness, if opportunely circuited with two iron laminations, can express a force (upon contact) 18 times stronger (tests were made with Anisotropic Ferrite Magnets).

Through the L/D ratio (thickness of the magnetic disk divided by its own diameter) and the diagram below, we can calculate the traction force (upon contact) of a permanent magnet, (axially magnetizing through the thickness) in isotropic or Anisotropic ferrite

.jpg)

.jpg)