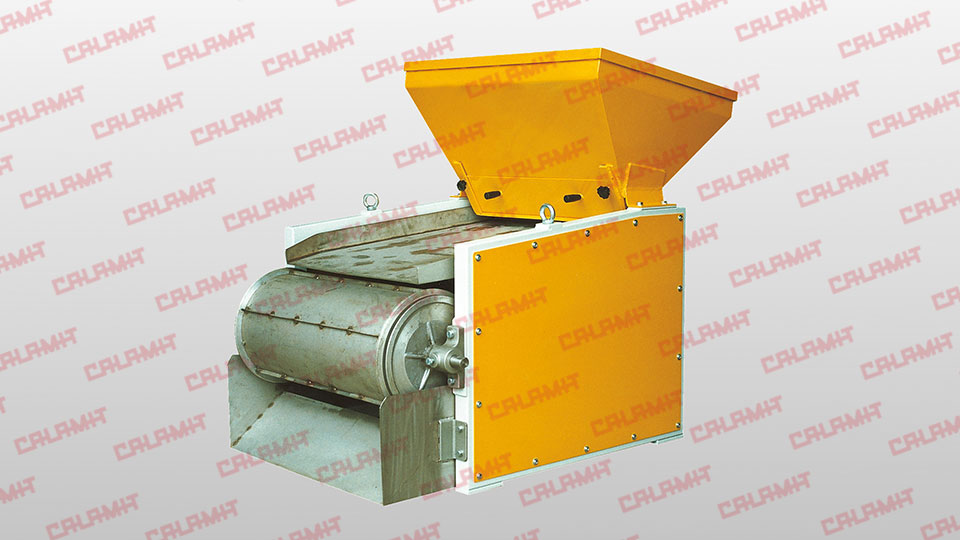

The CMD magnetic grading machine are used for automatically extracting iron magnetic metals from inert materials in recycling facilities, and for treating waste materials, in the food, plastic and wood industry. It can be used also to recovery iron metal from the crushing of appliances, cars, “computer” WEEE, and for the glass and ceramic industries.It is essential for the crushing of minerals.

These permanent magnet systems simplify the separation of iron material allowing for automatic recovery without production stoppage, saving blade shredders, mills and grinders from potential breakage, and guaranteeing a final product with no magnetic steel iron.

The magnetic sorter being conducted is very versatile in that it can be created both with a permanent magnet internal drum, and with an electromagnetic nucleus. CMD is recommended for working small and medium sized material.

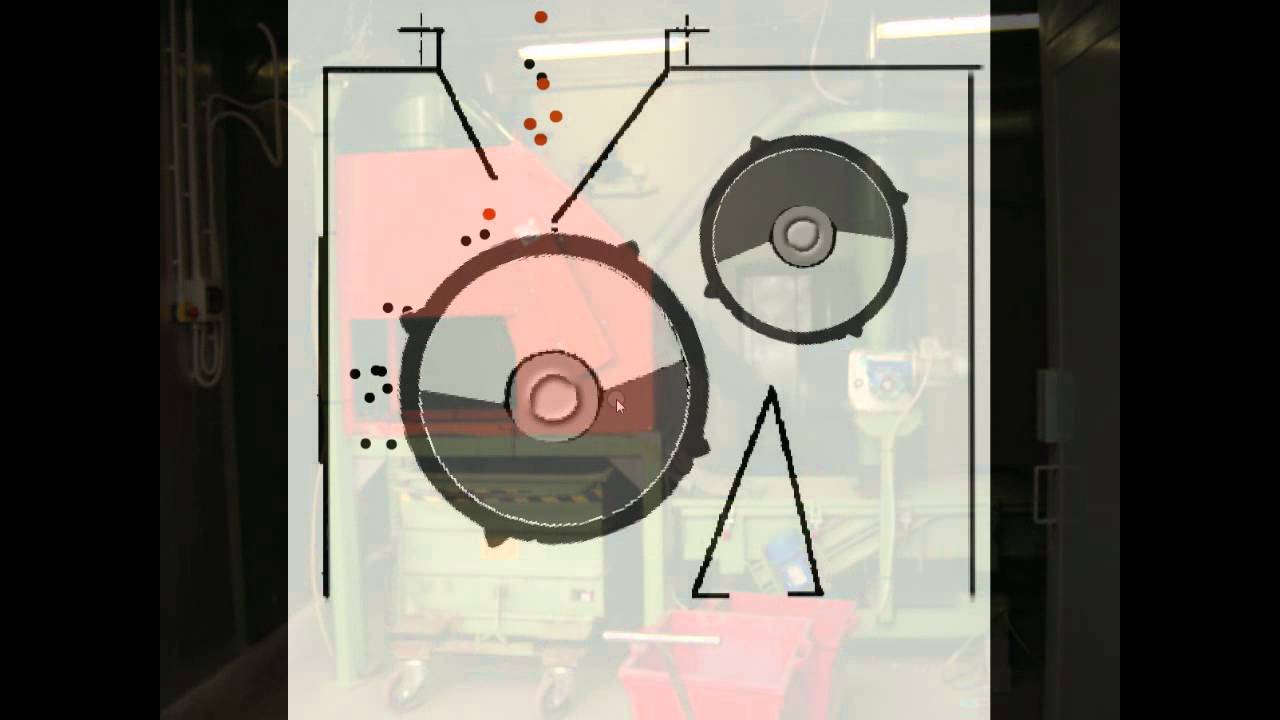

The materials to be treated, are conveyed in a suitable large loading hopper, when falls, thanks to gravity, through an adjustable flap, on a vibrating plane in stainless steel. The material then comes into contact with the DT magnetic model, which is made of an internal magnetic nucleus half moon shaped, and an external layer, built in non magnetic stainless steel, which circulates independently from the nucleus, controlled by a gearmotor.

The inert material will fall, thanks to gravity, into the first discharge opening, while the iron material pulled by the magnetic field will then be released in the subsequent discharge opening.

The ferrite permanent magnets allow for an almost unlimited time duration, and the CMD Magnet system does not require any maintenance, since it is self-cleaning.

If a higher magnetic force is needed, for equal sizes, extremely powerful iron removal drum devices can be created, using rare earth magnets that allow for the tripling of a magnetic attraction force, particularly useful for the separation of powders with paramagnetic particles or at a low permeability.

We can produce any format upon request.