Metal Detectors are electronic devices suitable for indicating, and eventually automatically diverting, through mainly mechanical and pneumatic systems, all types of metals within productive flows in recycling facilities and in waste and wood treatment, essential for the food industry, in plastic, in the crushing and recovery of household appliances, cars, “computer” weee, mineral crushing facilities, and in the glass and ceramic industries.

Function is based on generating a high frequency magnetic field via a transmission coil, captured by a second receiving coil. When there is no metal passing, this system is perfectly balanced: but otherwise there is an unbalance in the magnetic field that produces a voltage difference in the receiving coil, generating an alarm for the relevant metals.

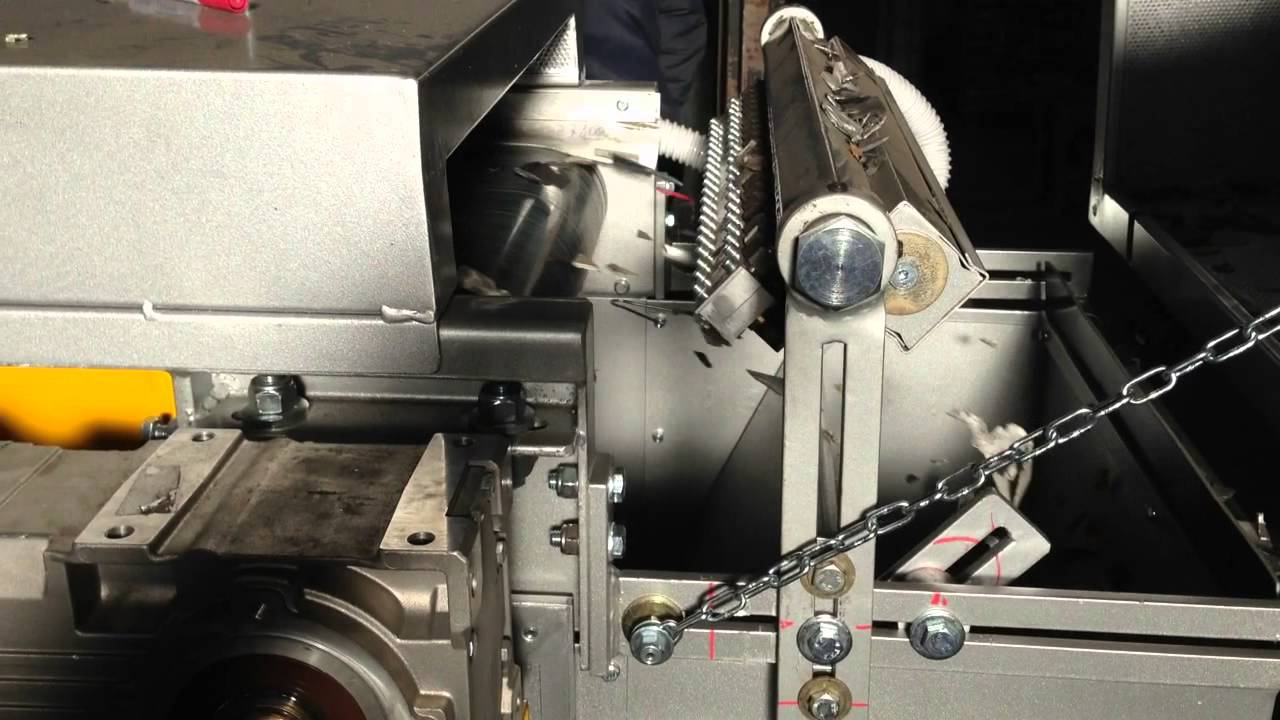

The metal detectors simplify the identification and extraction of metallic materials, even without production stoppages, preserving grinding and mill blades, in addition to guaranteeing a final product with no metal pollutants.

The positioning of the metal detector is a function of the type of model installed, and can basically be divided into three types:

1) plate metal detector: usually mounted below the conveyor belt;

2) tunnel metal detector: the conveyor belt is sliding inside and the material to be tested is passing on it;

3) pipe metal detector: to be used when the material to be verified passes through a pipeline.

The installation of the metal detector must be done on the apposite structure appropriately calculated and sized, paying attention to the presence of near metallic particles: these, in fact, within a certain range, if detected, can trigger the device and generate false alarms.

Depending on the product to process and on the dimensions to be detected, metal detectors with various sensibilities and electronic boards can be created.