These permanent magnet systems simplify separation of ferrous material, allowing for automatic recovery without production stoppage, saving blade shredders, mills and grinders from potential breakage, on top of guaranteeing a final product with no magnetic steel iron.

They are generally suspended at around 100/400 mm above the Conveyor belts or by chute, at the exits of belts, augers, redlers, Vibrating Feeders, or similar, used in conducts falling due to gravity or in forced ventilation.

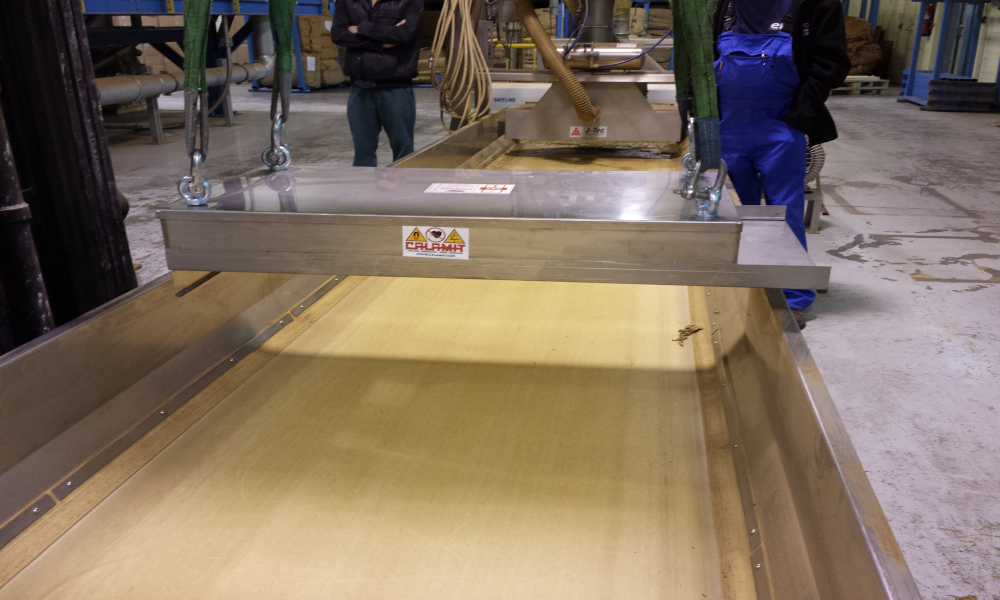

The TED separator must be mounted on a special structure calculated and sized so as to sustain the weight of the magnet and the ferrous bodies attracted by it, ensuring that there are no high permeability metallic structures or mat support rollers under the magnetic field, since these would completely or partially nullify the attraction capabilities of the iron removal system.

In order to facilitate separation and to help keep the ferrous material that was captured, the TED can, if needed, be supplied with a magnet surface in steps, or with cleaning systems with rapid folding or sliding.

Ferrite permanent magnets allow for almost unlimited time duration, and the TED Magnet system does not require any maintenance, aside from scheduled and periodic cleaning/removal of the captured ferrous material.

If a higher magnetic force is needed, in the same dimensions, extremely strong iron removers can be created using rare earth magnets, which allow for a tripling of the magnetic attraction force.

We can provide any format upon request.