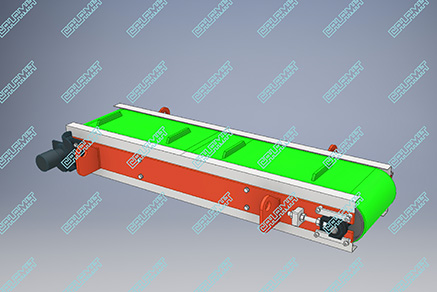

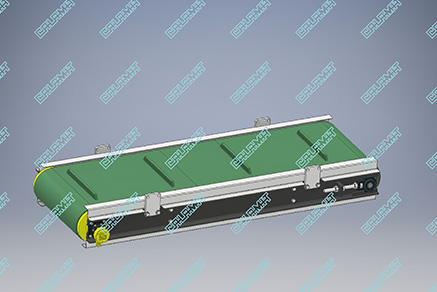

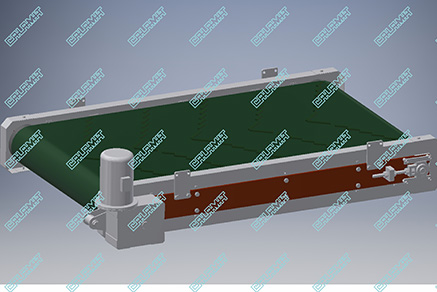

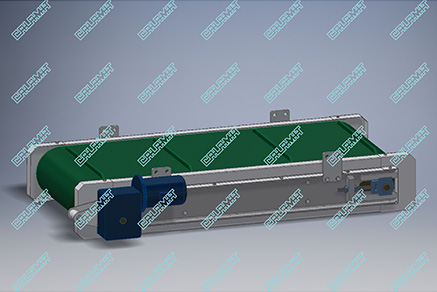

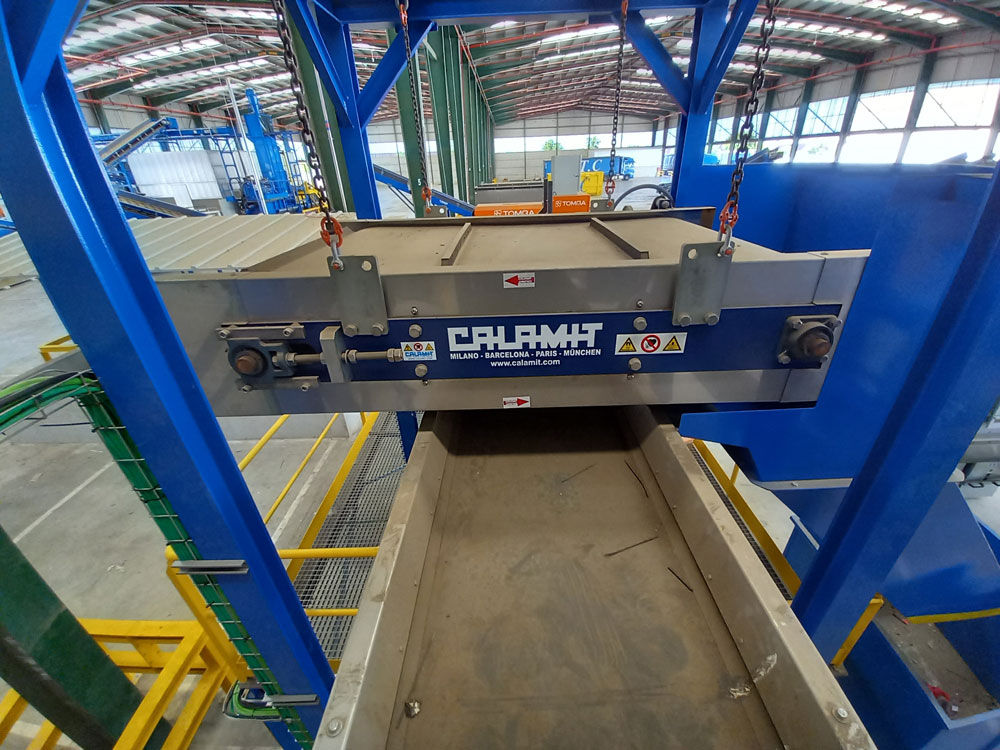

Type DMO automatic cleaning magnetic iron removers are cheap devices suitable for extracting magnetic ferrous metals from inert materials in recycling plants and waste treatment facilities.

These permanent magnet systems works thank to a magnetic circuit sized based on the necessary attraction distance, taking into account the layer and the type of material being transported, around which an extracting tape is wound, which automatically separates, without production stoppage, any ferrous material, allowing for the recovery of magnetically permeable material and preserving the blade shredders, mills and grinders from potential breakage, besides guaranteeing a final product exempt from magnetic steel iron.

They are generally suspended transversely at around 100/400 mm above Conveyer belts and Vibrating Feeders, or longitudinally at the head of transport and conveying systems.

In order to optimize separation and to help remove the captured iron material, the DMO mat with strips/porters or various sizes and numbers can be supplied if needed; moreover, it can be made with oil resistant rubber. The ferrite permanent magnets allow for almost unlimited time duration, and the DMO Magnet system does not need any sort of maintenance, aside from substitution of the used mat and bearings following scheduled and periodic maintenance.

If a higher magnetic force is needed, extremely strong iron removers can be created using rare earth magnets, which allow for a tripling of the magnetic attraction force.

We can provide any format upon request.