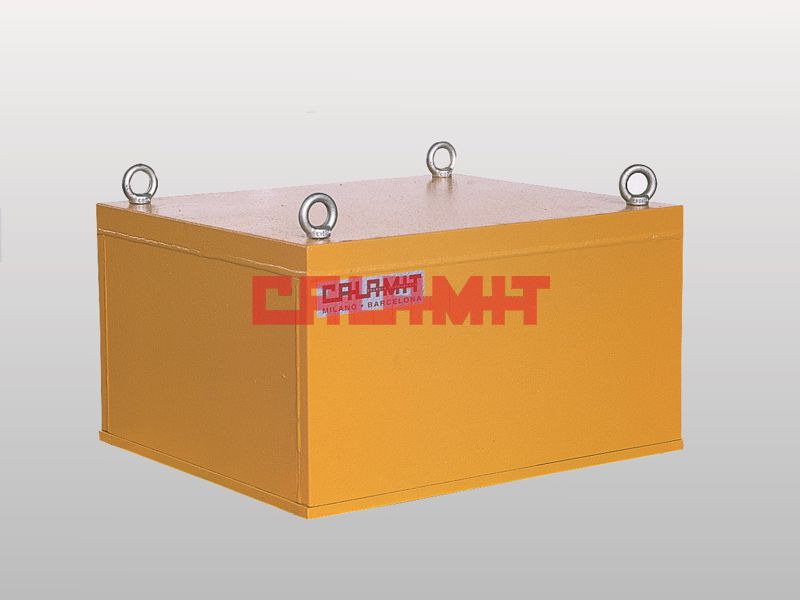

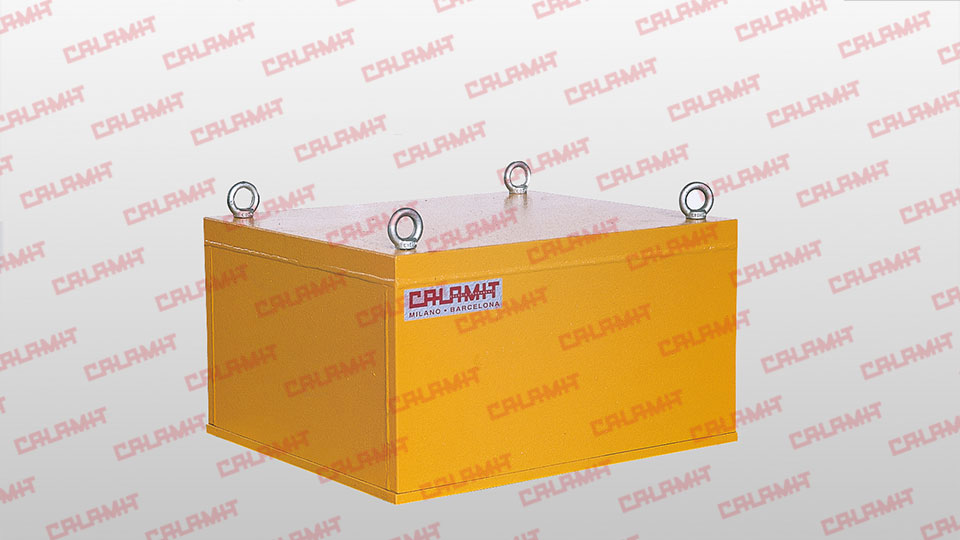

Electromagnetic type DEP iron removers are devices suitable for extracting magnetic iron from inert materials in recycling plants and waste treatment facilities, in the food industry, plastic and wood, in the recovery of metal ore from crushed appliances, cars, “computer” weee, mineral crushing facilities, and are essential for the glass and ceramic industries.

These electromagnetic systems works thanks to a coil wound around a nucleus that, fed by direct current, creates an opportunely sized magnetic field based on the necessary attraction distance, taking into account the layer and the typology of the transported material, allowing for the automatic recovery, without production stoppage, of permeable magnetic material, and preserving blade shredders, mills and grinders from potential breakage, besides guaranteeing a final product free from magnetic steel iron.

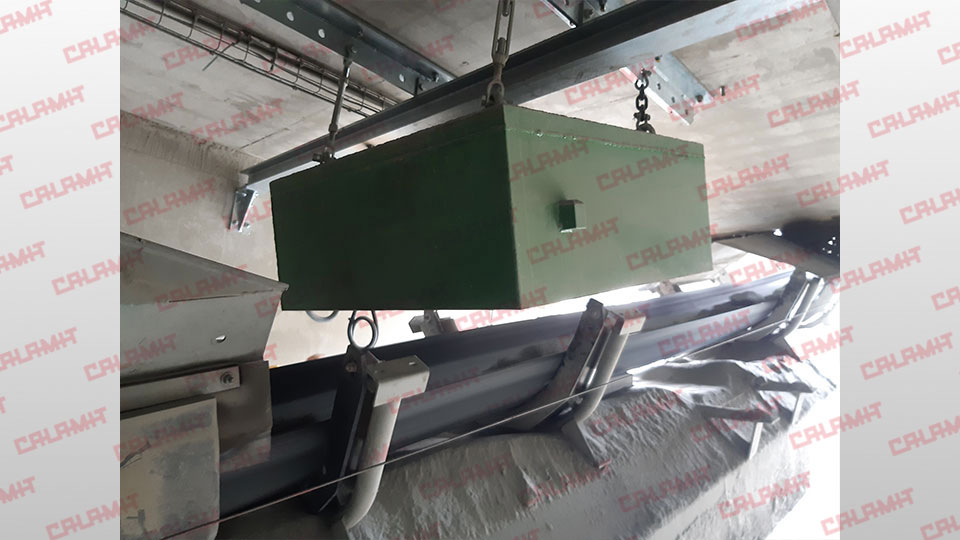

The DEP series is recommended for automatic separation of high volumes. It is generally suspended at around 100/600mm transversely above Conveyer belts and Vibrating Feeders, or on the head of the transport and conveying system. This electromagnetic system is also used where, due to production logic, there is not need for a permanent separation, and therefore the essential advantage is represented by the possibility of inserting/removing the magnetic field with a simple switch, and avoiding the systematic attraction of the iron material that is moving below.

The DEP separator must be mounted on a special structure appropriately calculated and sized so as to sustain the weight of the Protective Electromagnetic Iron remover and the iron bodies attracted by it, ensuring that there are no high permeability metallic structures or mat support rollers under the magnetic field, since these would completely or partially void the attraction capabilities of the DEP iron removal system. The adequate circuit of the coils (in C class) allows for an almost unlimited time duration, and the DEP electromagnetic system does not need any sort of maintenance.

Upon request, the DEP can be supplied with an electric command center and, if needed, a magnetic field regulator. The duration of the isolation of electro-technical products is influenced by many factors, among which, very importantly, is temperature.

The following table shows the division into temperature classes and the relative temperature intervals. The DEPs require direct current electric feeds at low tension, and are supplied with an electric control panel.

Remember that the operating temperature greatly influences aging, especially with isolating materials; to this end many electro-technical devices are designed with a thermal class: this represents the maximum appropriate temperature for the product in normal operating conditions.