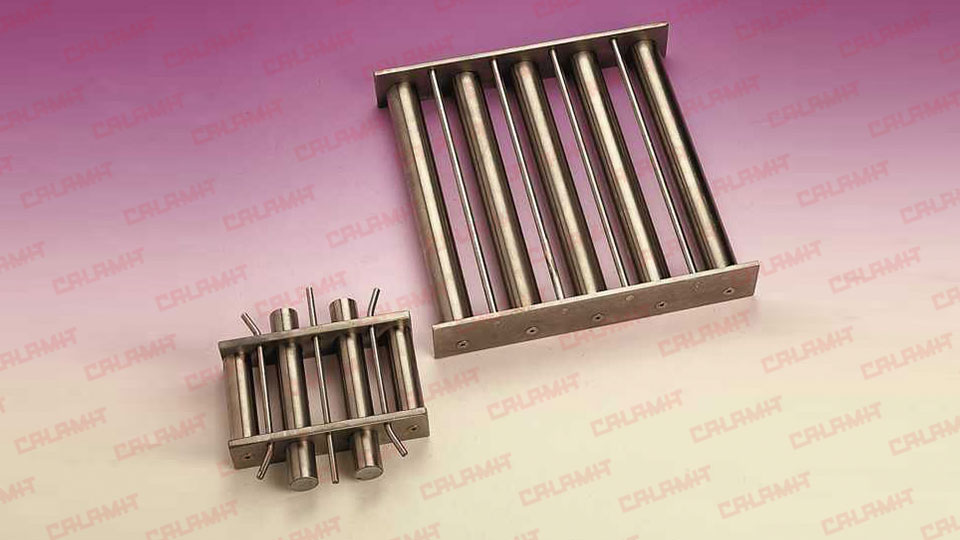

Grid magnetic iron removals are cheap devices suitable for extracting magnetic ferrous metals from inert in recycling plants and waste treatment facilities, in the food industry, in plastic and in wood, in the recovery of ferrous metal from the crushing of appliances, cars, “computer” weee, mineral crushing facilities, all essential for glass and ceramics.

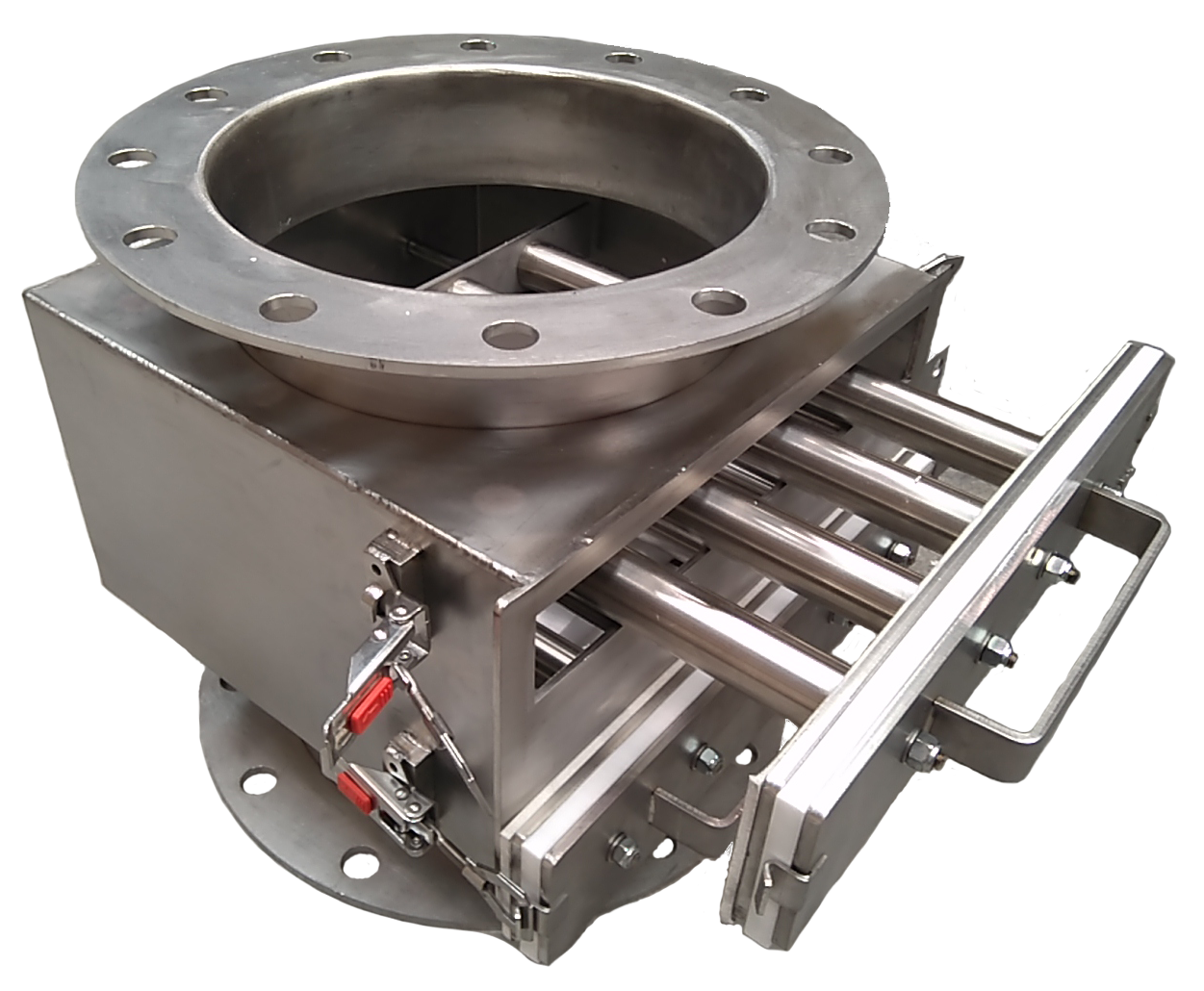

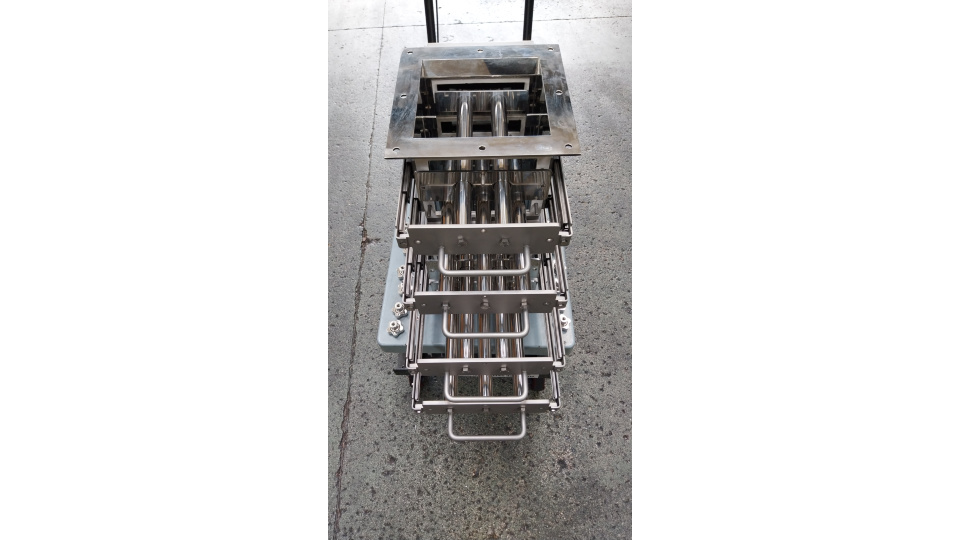

The magnetic grid is used where there are hoppers, exiting from or being loaded on Conveyor belts and augers, in suction transport conducts or in gravity falls, for the iron removal of grains, flour, powders, plastic granules, sawdust, etc.

These permanent magnet systems simplify separation of ferrous material, allowing for automatic recovery without production stoppage, saving blade shredders, mills and grinders from potential breakage, on top of guaranteeing a final product with no magnetic steel iron.

The magnetic field blocks the passage of any ferrous object, which, being located in the inferior section of the magnetic candle, remains safe from any potential detachment caused by the falling material.

Ferrite permanent magnets allow for almost unlimited time duration, and the magnetic grid does not require any maintenance, aside from scheduled and periodic cleaning/removal of the captured ferrous material. For cleaning, simply remove the grid from the housing, and wipe it with a cloth or with compressed air.

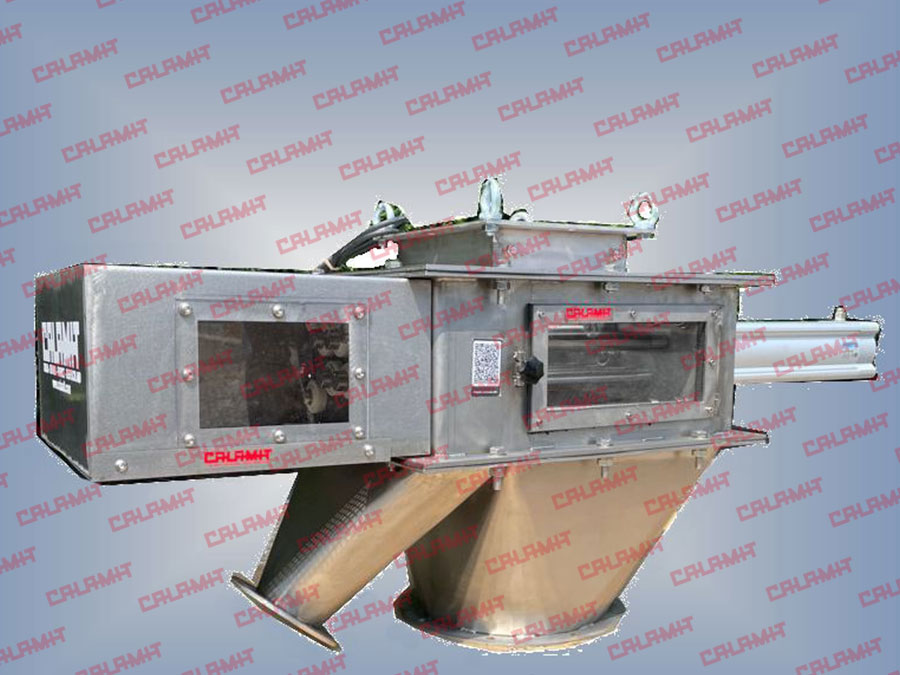

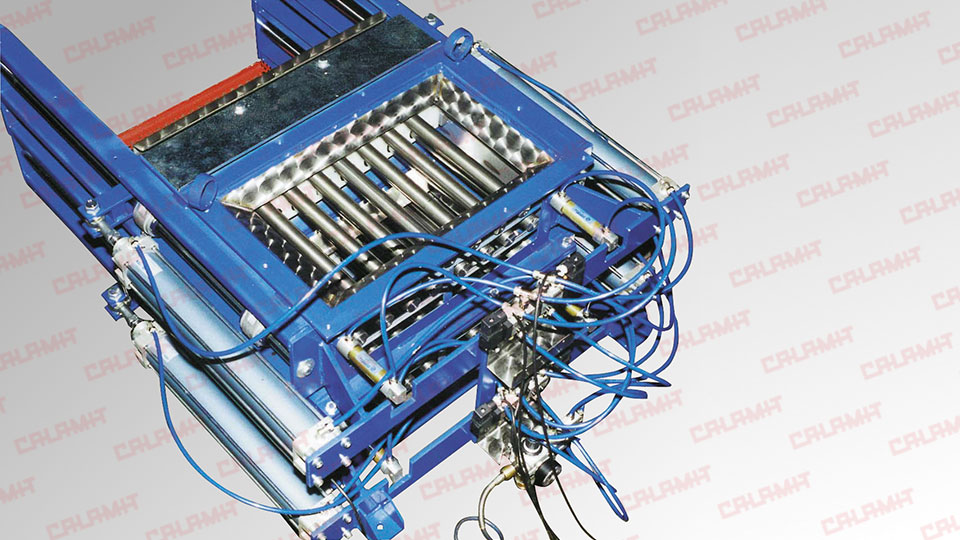

In order to further simplify this operation, Calamit has created quick cleaning systems. The GCA model is self-cleaning and works thanks to a pneumatic systems, which allow for the discharge of ferrous material captured in a dedicated collection container.

If a higher magnetic force is needed, in the same dimensions, extremely powerful iron removers can be created, using Rare earth Neodymium magnets, which allow for the expression of extremely strong magnetic forces.

We can provide any format upon request.