Alnico Magnets were discovered thanks to the intuition of Mishima, a Japanese man who, in 1936, when mixing the right proportions of several metals, invented the first important permanent magnetic material.

The Alnico 5 alloy, which is by far the most widely used and requested by the market, is made mainly from 24% cobalt + 14% nickel + 8% aluminum +3% copper + the remaining in iron.

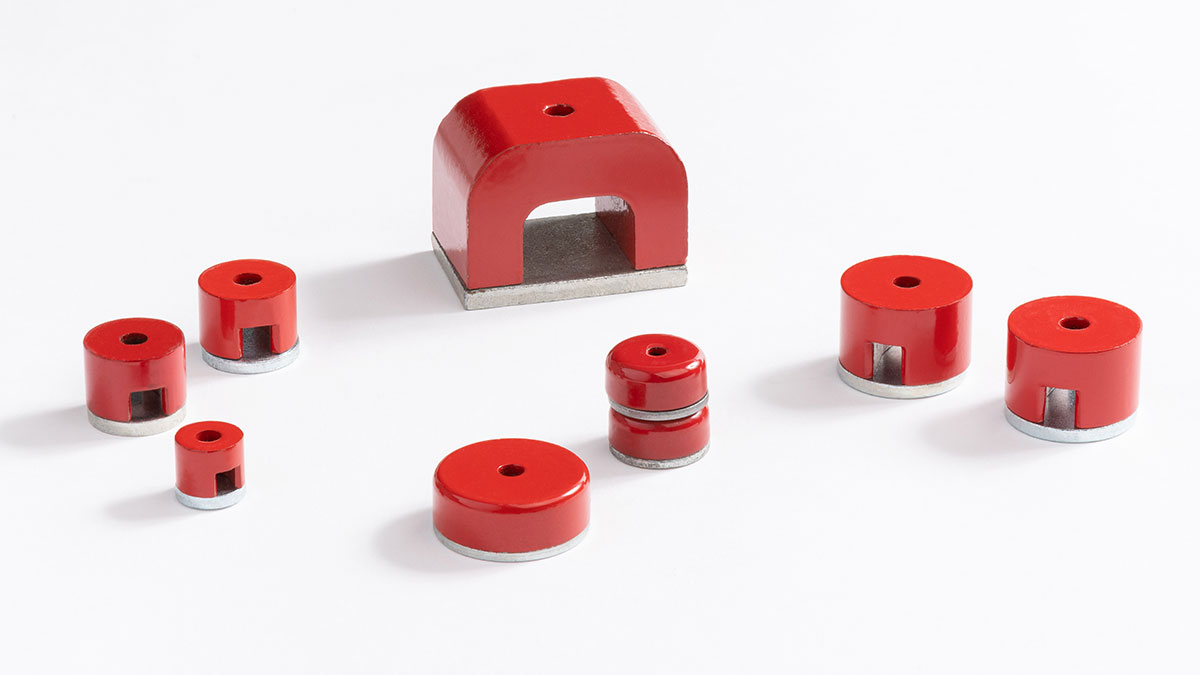

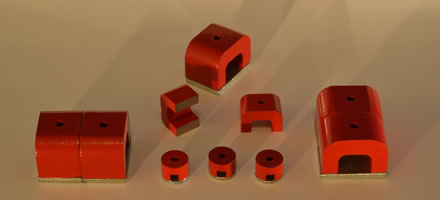

In order to obtain different Alnico alloys, one just needs to change the formula. Even though stronger and cheaper materials had come about, alnico is still widely used especially due to its characteristics of very low coercive field that allows for demagnetization and magnetization with applications at lower levels of power consumption.

Due to the elevated use of cobalt, this material undergoes significant price variations over time based on the valuation of the raw material (only 99.99% pure cobalt is used), which practically only comes from Zambia and the Democratic Republic of Congo. Moreover, alnico is still the most resistant magnetic material ,to highest temperatures (Curie point 860°C).

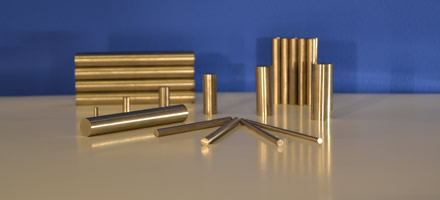

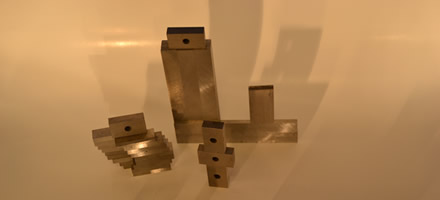

Calamit has the technology to cut and magnetize alnico in all directions, while taking into account that it is an anisotropic material, which has a preferential magnetic direction.