The SMNF Type Non ferrous metal separators are devices suitable for extracting metals from Inert Materials in recycling plants and waste treatment facilities, in plastic and wood recovery plants, in the recovery of metal from appliance crushing, cars, “computer” weee, and is essential in glass grinding plants and also in plants to recover aluminium cans.

Everyone knows that magnets attract iron, but not many know that permanent magnets are also able to reject virtually all non ferrous metals.

By creating an alternate magnetic field and exploiting the exceptional residual induction of rare earth magnets (neodymium iron borum), and making them spin at high velocities (from 500 to 4000 rpm), we obtain a magnetic field capable of rejecting any non ferrous metal (currently, the only exceptions are some types of stainless steel and small sized copper wires).

The rotor’s magnetic fields are created based on the type and the dimensions of the material to be separated, and the separator is able to treat up to 140 cubic meters of material per hour. The rejection force acting on the material will vary depending on the size and particularly the electric resistance of the metal to be separated.

The induction current that is generated is called Eddy current, or Foucault current, and the visual effect obtained with non ferrous metal separators is almost science fiction.

The demonstration facility that Calamit has at its European subsidiaries and that is has already exhibited in various exhibitions, attracts the attention of visitors who are visibly affected by this incredible technology.

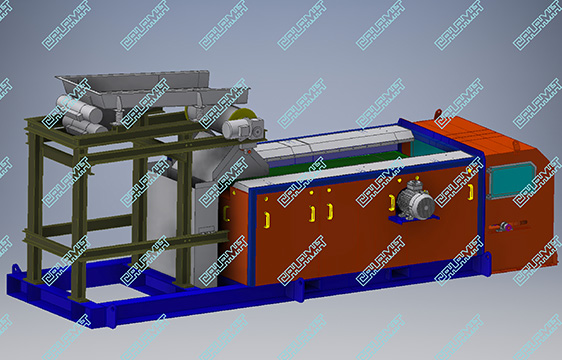

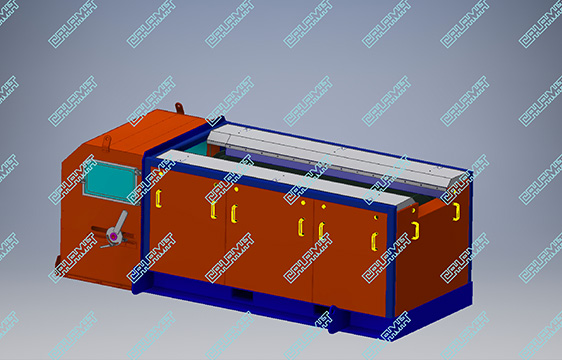

SMNF is just a conveyor belt upon which material to be separated is placed and suitably deferrized upstream. It is preferably to feed the SMNF with a vibrating table that distributes the product in a single mono layer close to the magnetic discharge roller (called a rotor); the non ferrous metal will tend to jump ahead on the conveyor belt or into a container, while the inert material will fall due to gravity into another container or into a dedicated conduct.

The mat will be controlled by a dedicated inverter, while the magnetic rotor will turn independently from the mat, controlled by a second inverter.