DT type magnetic iron removals are devices for automatically removing of magnetic iron metals from inert s in recycling facilities and for treating waste materials, in the food industry, in plastic and in wood, in the recovery of iron metal from the crushing of appliances, cars, “computer” weee, for the glass and ceramic industries, and essential for the crushing of minerals.

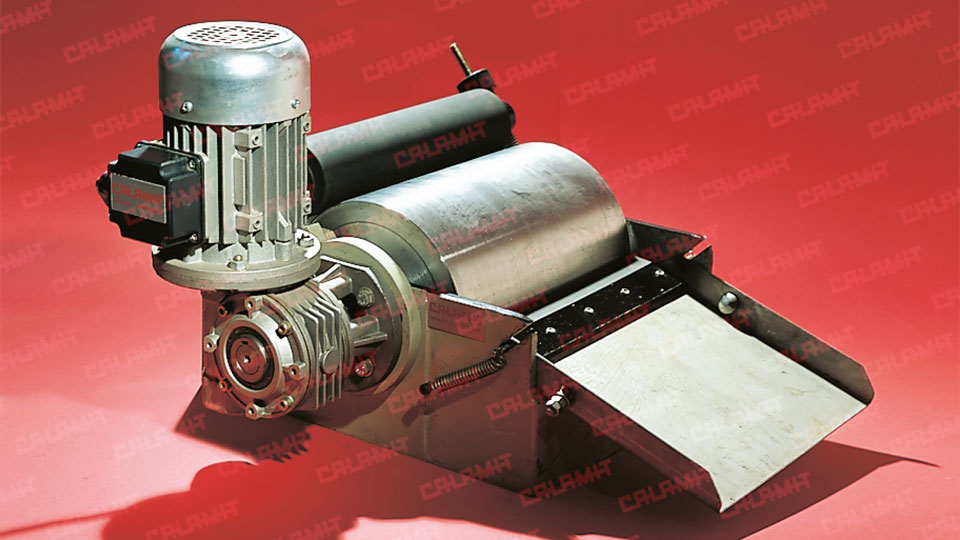

These permanent magnet systems simplify the separation of ferrous material, allowing for automatic recovery without production stoppage, saving blade shredders, mills and grinders from potential breakage, in addition to guarantee a final product with no magnetic steel iron.

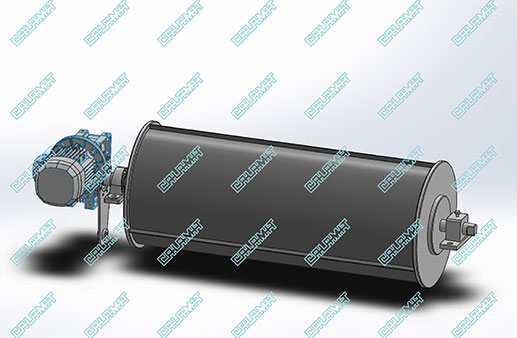

The magnetic drum is very versatile and can capture iron in small and large pieces and can be produced even with diameters of 1000/1500 mm with magnetic or electromagnetic circuits.

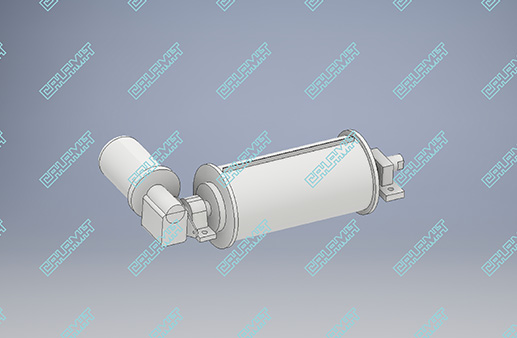

The DT magnetic model is made up of an adjustable half moon shaped internal magnetic nucleus that can be fixed, to be adapted to any type of flow.

The Magnetic drums are usually placed on the output of the Conveyer belts or augers and in relation to the slides and vibrating planes. They must be mounted, making sure that there are no high magnetic permeability metallic structures close to the magnetic field, since these would nullify, in whole or in part, the attraction qualities of the iron removal system.

Permanent Magnets in ferrite allow for almost unlimited time duration, and the DT magnet system does not require any maintenance, since it is self-cleaning.

If a higher magnetic force is needed, for equal sizes, extremely powerful iron removal drum devices can be created, using rare earth magnets that allow for the tripling of a magnetic attraction force, particularly useful for the separation of powders with paramagnetic particles or at a low permeability.

We can provide any format upon request.